Thermoposa

The modern solution for squaring the window opening

The traditional subframe is normally built with 3 sides, two uprights and an upper cross-piece, which are usually made of wood (generally poor-quality spruce), pressed metal sheet (which often also contains the roller shutter guide) or with a tubular galvanised metal profile.

All the described subframes have some issues that prevent their use in a safe, durable, and high thermal-acoustic efficiency installation:

1. The solid wood subframe is fine from a thermal point of view, but it could have durability issues as it can rot in contact with the moisture that condenses in the wall near the connecting node.

However, the most serious problem is that it cannot always guarantee a standard mechanical seal of the screw anchor of the window frame as there are often defects (knots, cracks, and resins) in the boards.

2. Compared to the mechanical seal, the galvanised steel tubular subframe is certainly more reliable because it is more robust and with a “standard” behaviour, but like the subframe made of pressed metal sheet it constitutes a thermal bridge capable of causing heat loss on the perimeter of the window due to the formation of condensation and mould on the parapets.

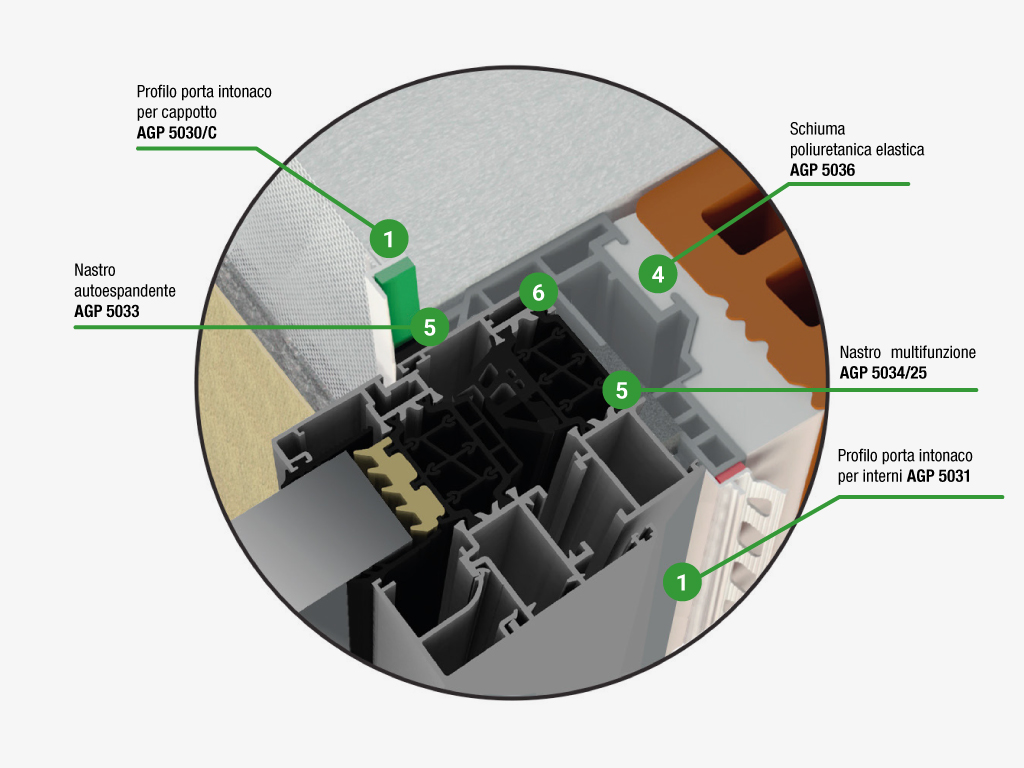

The installation system

Marble cutting

It is made with an extruded L-shaped profile in recycled PVC which has both shoulder and abutment. On the surface of the shoulders, specific ribs are obtained to accommodate the various accessories that are necessary for a rapid assembly and fixing to the wall.

The edges are shaped for the application of the plaster holder profiles which ensure a proper formation of the primary node and therefore a correct sealing to the wall in an elastic way and without the formation of cracks.

Different models are available according to the size of the shoulders and the abutments: there are 3 models of the shoulders characterised by a different depth, to be used according to the thickness of the frame and/or the accessories to be inserted (roller shutter guide or retractable mosquito mesh guide). Each shoulder is available as standard with two different abutment sizes: 49mm for covering the window frame or 25mm to leave it partially visible.

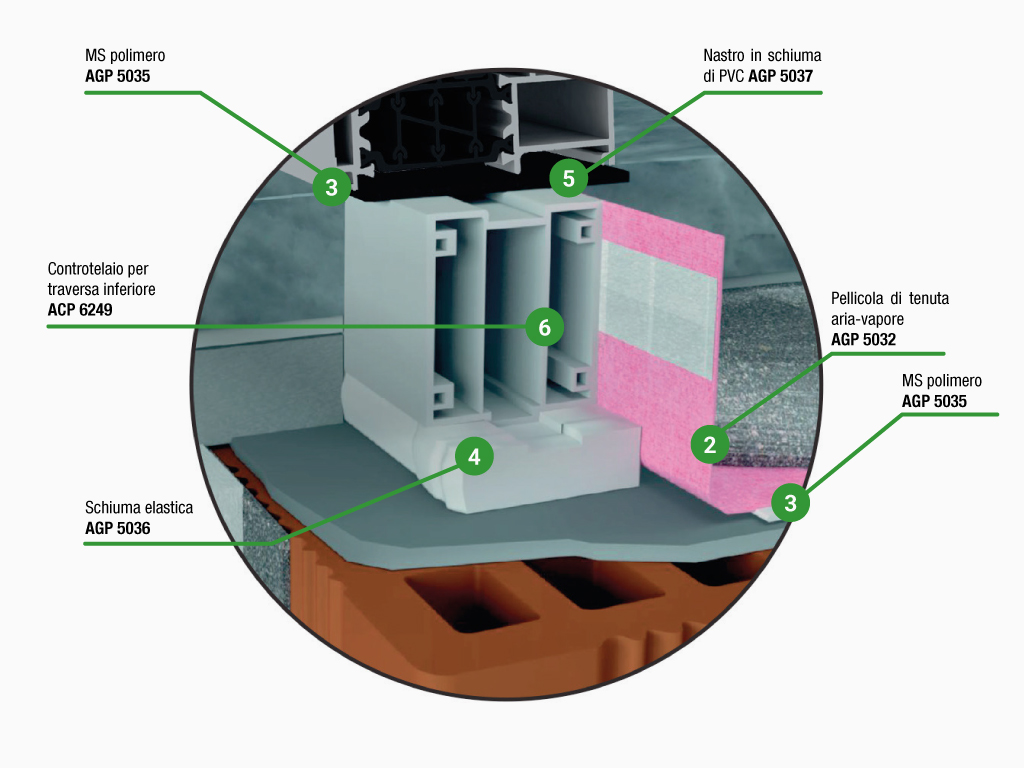

Installation of the new window

The new window is built with a special tubular PVC box, which is modular and can be walked on. This material is inert to water so the lower cross-piece can resist for a very long time without rot problems and deformation even in situations of high humidity, more likely in the lower part of the window.

To improve the problem of the thermal break of the French window in the thickness of the screed between the floor and the slab, the upper and lower surface of the cross-piece has been shaped in such a way as to allow the interlocking of several elements to form a base of appropriate dimensions that continuously connects the French door cross-piece to the slab. 40mm and 20mm cross-piece available.